Most U.S. nuclear power plants are fueled by uranium oxide (urania), which has a sufficiently high fissile density, exhibited good stability, and effectively retained fission products. Urania is also highly resistant to radiation damage, though it does suffer from being harder to extract energy because of its relatively poor thermal conductivity.

While uranium is found in rocks all over the world, uranium production in the United States crawled to a near-total halt after 1980 – as did construction of new nuclear power plants – in the wake of an amplified anti-nuclear campaign that continues to this day. Since 1992, most uranium used by America’s aging nuclear power plants comes from Canada (27%), Kazakhstan (25%), Russia (12%), Uzbekistan (11%), and Australia (9%).

The Trump Administration wants to limit U.S. reliance on foreign sources for uranium ore and processed uranium oxide fuel, much of which has come from Russia. Under policy announced in May, the White House sounded the alarm that the nuclear fuel cycle infrastructure has severely atrophied, with only about 5% of fuel used in U.S. reactors coming from domestic sources.

One reason has been the federal regulatory stranglehold on permitting uranium mines, but another is a 1977 federal policy that bars reprocessing of used nuclear fuel for commercial reactors. A Trump executive order seeks to ensure that Americans can mine, process, and refine nuclear fuels – as an issue of national security. A second executive order addresses “immediate measures to increase domestic mineral production,” including uranium.

Many U.S. advanced reactor developers are testing their designs with Tri-structural ISOtropic particle fuel. TRISO, which the DOE has called “the most robust nuclear fuel on Earth,” also has uses in older pebble-bed designs. Industry and government officials see TRISO as a cost cutter for the broader microreactor industry – and for high-energy-using industries.

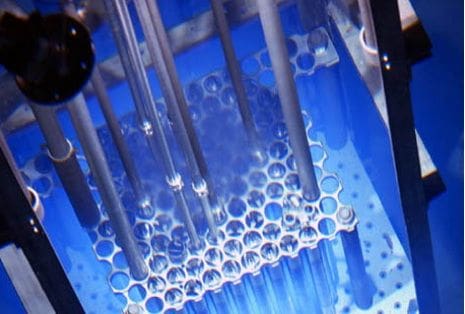

TRISO is structurally more resilient to neutron irradiation, corrosion, oxidation, and high temperatures than uranium oxides. TRISO fuel consists of tiny, seed-sized particles that can be molded into cylindrical pellets or billiard ball-sized spheres (“pebbles”) for use in either high-temperature gas or molten salt-cooled reactors. As each TRISO particle acts as its own containment system, TRISO can retain fission products under all reactor conditions.

BWX Technologies, in conjunction with the DOE’s Advanced Gas Reactor Fuel Development Program, just completed a new uranium nitride TRISO fuel production line at its technology center in Lynchburg, Virginia. BWX designs and manufactures TRISO fuel for the Defense Department’s Pele program and evaluates TRISO as a fuel for advanced reactors.

BWXT is the first U.S. company to manufacture irradiation-tested uranium oxycarbide TRISO fuel using production-scale equipment. The TRISO production line is co-located with BWXT’s existing uranium processing operations to establish a vertically integrated facility that spans the TRISO fuel cycle from feedstock preparation to uranium recovery and purification.

Another TRISO manufacturer, Oak Ridge-based Standard Nuclear, was the first company chosen by the Department of Energy to establish a domestic nuclear fuel supply chain for testing new reactors. In making the announcement, Energy Secretary Chris Wright said, “Advanced nuclear reactors will be a game changer for the U.S., and with that comes the need to fabricate the fuel for these reactors.”

In addition, TRISO-X, a subsidiary of X-energy Reactor Company, LLC, is manufacturing its own proprietary version of TRISO fuel for the commercial microreactors it is developing in conjunction with the Department of Defense’s Defense Innovation Unit and the U.S. Air Force. X-energy will be using its TRISO-X fuel to power its Xe-100 high-temperature, gas-cooled reactors as grid-scale energy solution for utilities, industrial consumers, and hyperscalers.

TRISO fuels are hardly new fuel technology. TRISO belongs to a broader class of particle fuels proposed in gas-cooled pebble-bed reactors as far back as 1944 – at the birth of the nuclear age – but are only now reemerging as “fuel of the future.”

Research on TRISO began in the 1960s but slowed after the U.S. panicked and the Nuclear Regulatory Commission smothered the industry. Those early designs relied on uranium oxide for the kernel to avoid internal pressure buildup from the formation of carbon monoxide gas.

There is also a strong connection between terrestrial TRISO development and space exploration, as the same principles of fuel stability at extreme temperatures apply. Moreover, with NASA and private entities planning for long-duration human missions, reliable and compact nuclear power systems may become mandatory – as they have been with nuclear submarines for decades.

Not everyone has staked the future of nuclear energy on TRISO.

Clean Core Thorium Energy is testing its patented Advanced Nuclear Energy for Enriched Life (ANEEL) fuel in its advanced test reactor at the Department of Energy’s Idaho National Laboratory (INL). The fuel has reached a burnup level of over 45 gigawatt-days per metric ton, outpacing the capabilities of conventional nuclear fuels used in pressurized heavy water reactors to generate electric power.

ANEEL uniquely combines thorium with high-assay, low-enriched uranium (HALEU) to offer what CCTE says is a safer, more efficient, and proliferation-resistant alternative for existing and future reactor fleets worldwide. Weakly reactive thorium is deemed a safer, cheaper alternative to uranium in nuclear reactors – and three times more abundant in nature than uranium.

Thorcon, founded by former MIT professor Jack DeVanney, has taken its molten salt reactor design, powered by thorium fuel and manufactured on an assembly line in a shipyard, to Indonesia, where it is already building a 500-MW prototype reactor that could be activated by 2029. The plant is based on technology developed by at Oak Ridge National Laboratory in the 1960s – but long abandoned thanks to nuclear fear.

Earlier this month researchers at Pacific Northwest National Laboratory began their review of another advancement in nuclear reactor fuel that may boost performance at power plants and reduce the quantity of spent nuclear fuel. GE Vernova’s Global Nuclear Fuel (GNF) loaded eight assemblies into a commercial reactor for two 24-month cycles and were relicensed and reinserted into the reactor for continued exposure.

The design uses full- and partial-length rods whose fuel pellets contain gadolinium, which absorbs neutrons to improve the utilization of the fissile content throughout the fuel cycle. Company officials are now awaiting the results of PNNL’s examinations of the twice-used rods.

Another possibility for expanding domestic nuclear fuel supply could come from repeal of the longstanding ban (initiated by President Carter) on reusing spent nuclear fuel – which has left 91,000 metric tons in storage around the U.S. A January 2025 Congressional report says that 95% of SNF consists of uranium from fresh fuel and 1% of fissile plutonium produced from irradiated uranium – all of which can be used in new fuel.

The U.S. developed the technology for reprocessing of SNF during World War II and – like France, Russia, and other nations today – operated some of the largest reprocessing facilities in the world. That is, until the anti-nuclear fervor ushered in policies that effectively brought nuclear energy development in the U.S. to a 40-year standstill.

Meanwhile, China has unveiled a fourth-generation fast neutron reactor that utilizes nuclear fuel more efficiently, reducing waste and enhancing energy output. According to Energy-Reporters, “They’ve built a reactor that breeds its own fuel.”

Duggan Flanakin is a senior policy analyst at the Committee For A Constructive Tomorrow who writes on a wide variety of public policy issues.

This article was originally published by RealClearEnergy and made available via RealClearWire.